30+ Years Experience

Aluminium Window Machine Manufacturer

CNC Aluminium Window Machine

CNC Aluminium Window Machine

About JH Machine

About JH Machine

Guangdong Jiahua Intelligent Equipment Co., Ltd. is dedicated to the design, manufacturing, and marketing of premium equipment for processing aluminum, insulated glass, and uPVC doors and windows. With more than three decades of expertise, a proficient workforce, and compliance with ISO 9001:2000 standards, we offer innovative, secure, and dependable machinery utilized in over 40 nations. Driven by our principle that “Details Determine Success, Quality Creates the Future,” we deliver customized solutions, strong after-sales service, and an extensive network of service centers to fulfill the requirements of our global clientele.

YEARS

0

+

Over 30 years of experience in the door and window processing machine industry.

PATENTS

0

+

More than 60 patents for door and window processing machine.

SETS

0

+

7,500+ door and window processing machines installations worldwide.

One-stop building of your doors and windows brand

service

What JH can offer

- Compliant with CE certification requirements

- Free component matching and support

- Comprehensive one-stop solutions

- Lifetime after-sales service

.webp)

JH provides end-to-end door and window processing solutions, from consultation to installation and equipment optimization, all tailored to enhance efficiency and quality. Our complimentary component customization ensures seamless integration with existing systems, improving performance and extending lifespan. With lifetime support, including maintenance and technical assistance, we minimize downtime and maximize productivity for our clients.

Quality Management

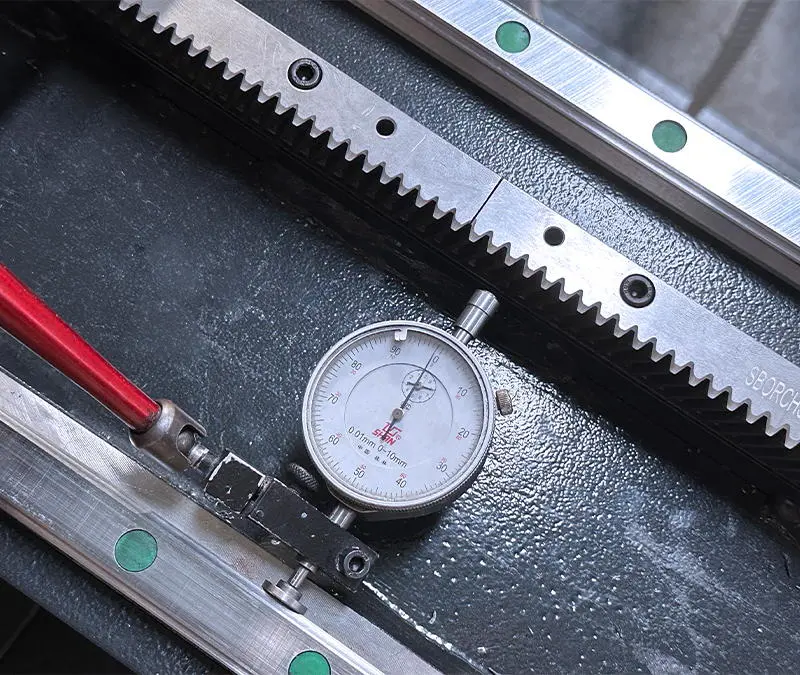

Parts Calibration Testing

Assembly Inspection

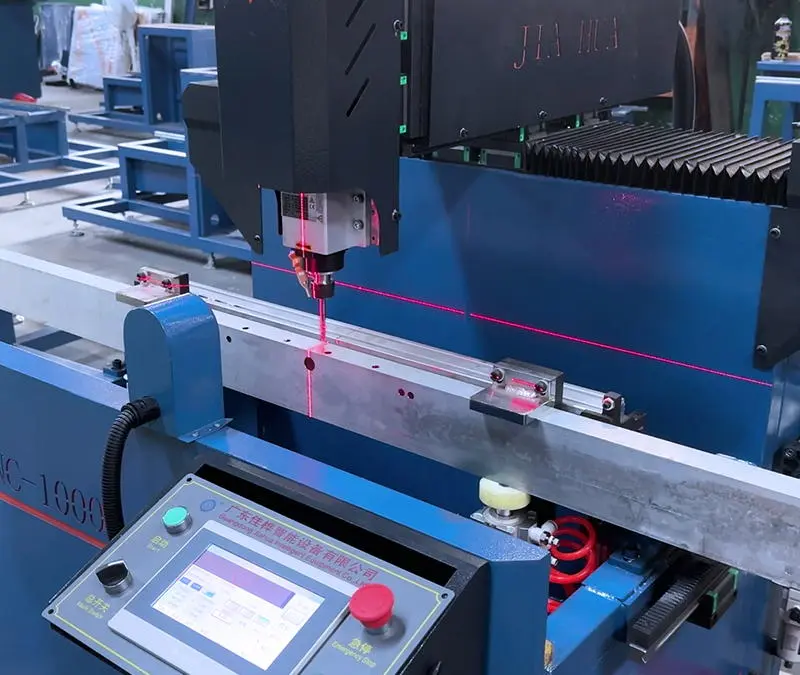

Finished Product Testing

What People Say

“JH’s aluminium window machines have top-notch quality and performance – a fantastic investment for our company!”

“The aluminum profile cutting machine is dependable and effective, ensuring our production runs more smoothly than ever!”

“The support team is exceptional, and the equipment operates without a hitch!”

“JH put me at ease when I first started aluminum window and door production.”