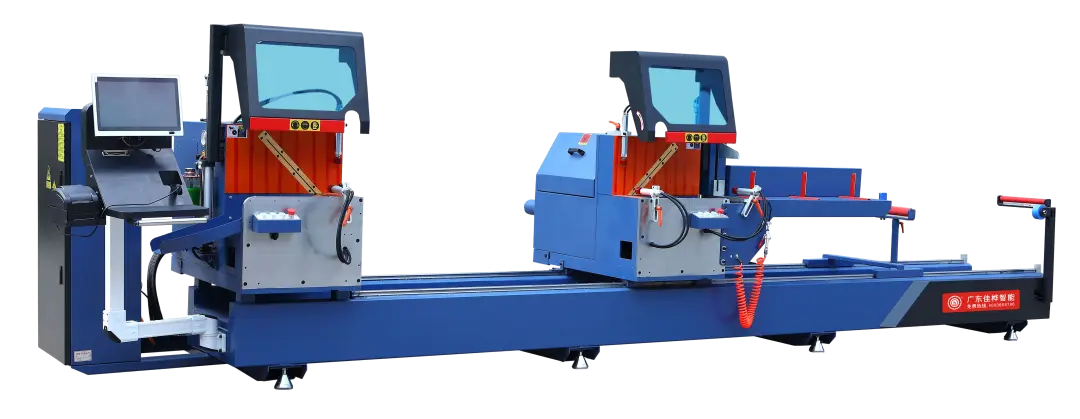

Automatic 45-degree Double Head Aluminum Cutting CNC Machine (Outward)

Automatic aluminum cutting CNC machine Features

The Automatic 45-degree Double Head Aluminum Cutting CNC Machine (Outward) With advanced CNC technology, this machine can automatically process profiles of varying specifications and dimensions, achieving accurate 45-degree cuts to meet the highest production standards.

Equipped with high-quality, aluminum-specific carbide saw blades, the saw guarantees excellent cutting performance. The high-precision spindle system ensures smooth blade rotation, significantly improving the surface quality of the workpieces. The air-liquid damping mechanism provides uniform feed, extending the lifespan of the saw blades.

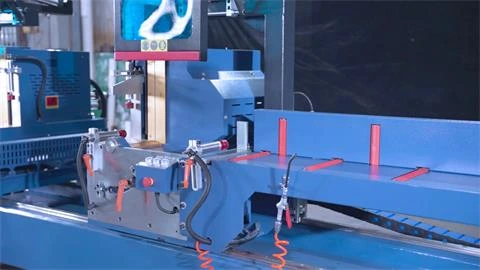

The feed mechanism uses imported guide rail and sliding block units, providing exceptional motion accuracy, while the precision linear bearings ensure high-precision repeat positioning. The automatic head rotation and bidirectional positioning system ensure stable and reliable clamping. The bidirectional pneumatic cylinder clamping mechanism enables fast and stable positioning and clamping operations.

For enhanced safety, the machine is equipped with an automatic opening and closing protective cover, and a spray cooling system is installed to ensure rapid cooling during the cutting process, optimizing both operational efficiency and operator safety.

Automatic aluminum cutting CNC machine Parameters

Cutting

| Feeding Length | 430~4500mm |

| Saw Blade Size | Ф550×Ф30mm |

| Sawing Range | 170×220mm |

| Rotational Speed | 3000r/min |

| Cutting Angle | Dedicated to 45° |

Power

| Input Power | 2×3.0kW |

| Input Voltage | 380V/50Hz |

| Air Pressure | 0.6~0.8MPa |

Machine

| Machine Size | 6100×1200×1600mm |

| Machine Weight | 2200kg |

| Air Consumption | 300L/min |

Automatic aluminum cutting CNC machine Details

Intelligent CNC control panel

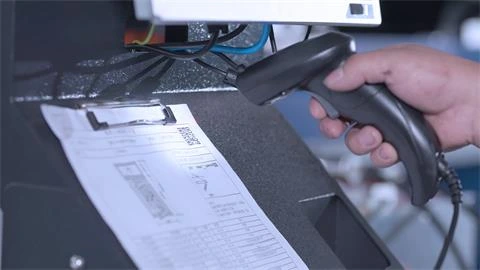

Digital code scanning production

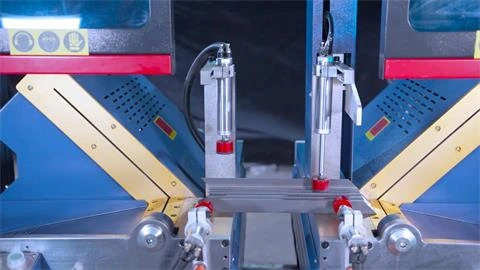

Profile cutting protective cover

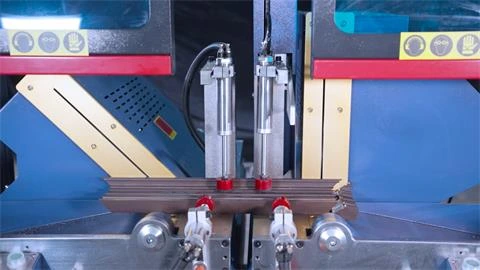

Independent Fixed profile pressing system

Aluminum profile feeding system