Automatic Aluminium Drilling Machine with Milling

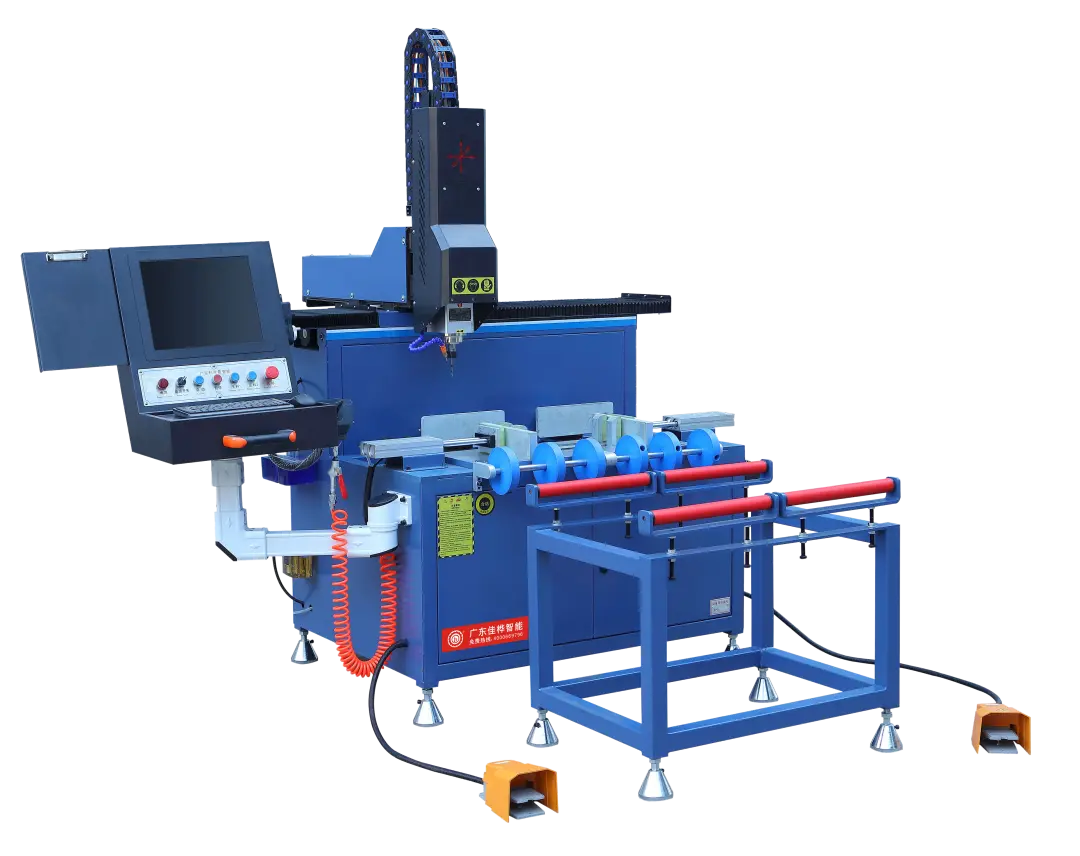

Designed for precise and efficient machining of aluminum profile process holes, the automatic aluminum drilling machine with milling combines high accuracy, advanced automation, and enhanced productivity.

Automatic Aluminium Drilling Machine with Milling Features

The Automatic Aluminium Drilling Machine with Milling is designed for precision machining of various process holes in aluminum profiles, including glue injection holes, movable angle code holes, dowel holes, corner protectors, and transmission rod notches. It features an exclusive chip removal design with a built-in waste collection box, ensuring a cleaner work environment.

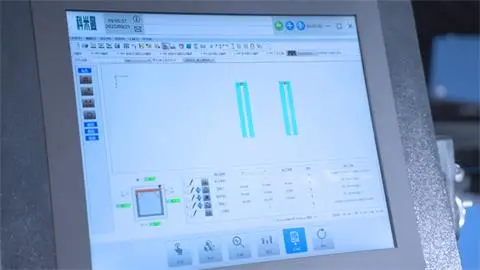

With high-precision linear motion components, ball screws, and gear racks, the machine delivers smooth operation and a positioning accuracy of 0.05mm. It comes equipped with a standard tool life management system and an automatic maintenance reminder function for optimal performance.

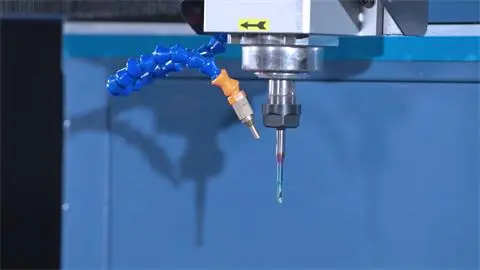

Engineered for efficiency, the machine utilizes a high-speed variable frequency electric spindle for stable, low-noise processing. Its dual-station design enables simultaneous operations, achieving six times the efficiency of traditional processing methods and allowing seamless operation even by general operators.

Automatic Aluminium Drilling Machine with Milling Parameters

Cutting

| Processing Angle | +90°~0°~-90° |

| Milling Size | ER32-Ф8 |

Power

| X-axis Servo Power | 0.75kW |

| Y-axis Servo Power | 0.75kW |

| Z-axis Servo Power | 0.75kW |

| Air Pressure | 0.6~0.8MPa |

| Input Voltage | 380V/50Hz |

| Total Power | 2.2kW |

Machine

| Spindle Speed | 0-5m/min |

| Machine Size | 7000×800×2000mm |

| Machine Weight | 900kg |

Automatic Aluminium Drilling Machine with Milling Details

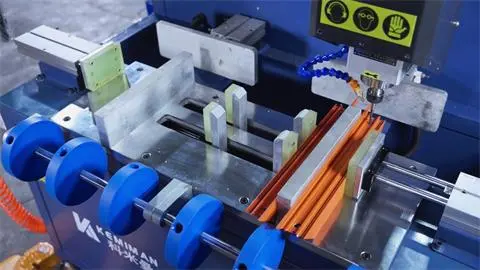

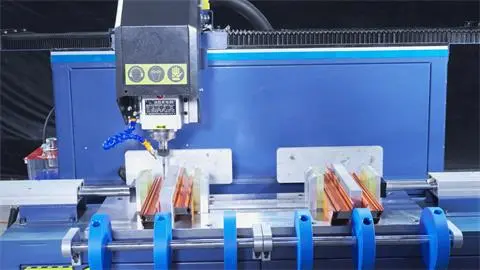

Dual-Head Drilling and Milling System

High-Precision Drilling and Milling

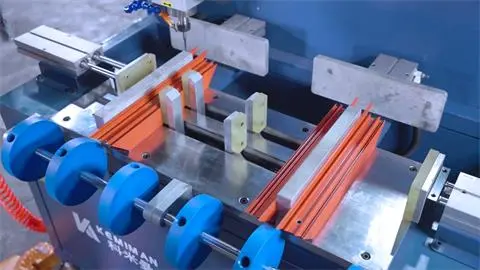

Stable and Precise Control System

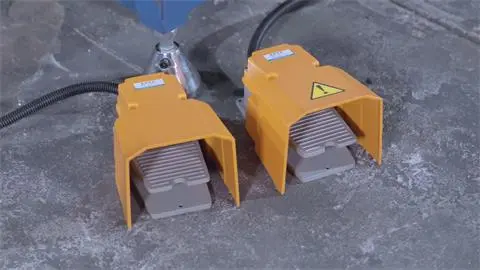

Foot Pedal Controller

Automatic Material Clamping System