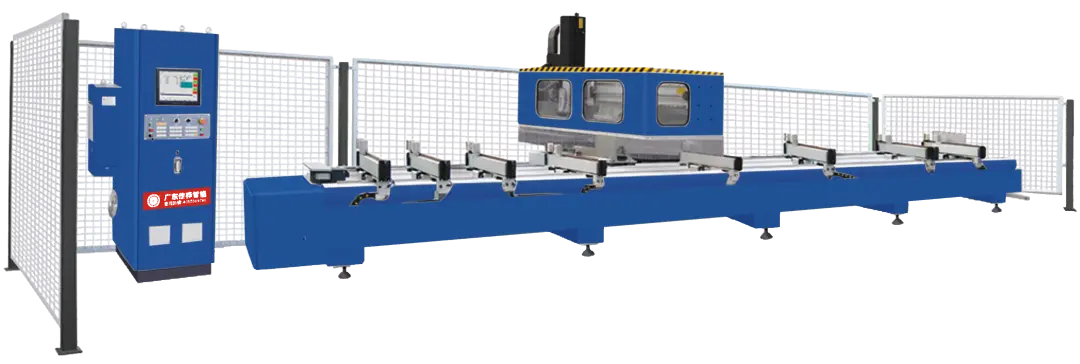

Automatic Four-axis CNC Aluminum Milling Machine (Cantilever)

Dual worktables can process two profiles or two different types of profiles simultaneously, with interactive loading that operates without interference.

Automatic Four-axis CNC Aluminum Milling Machine (Cantilever) Features

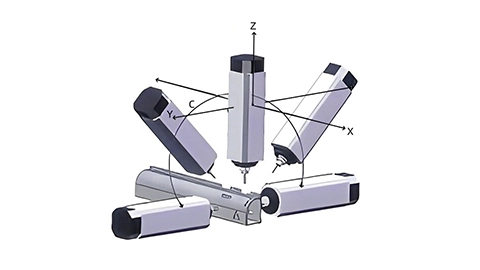

JH advanced aluminum window and door processing equipment is designed to deliver precision, efficiency, and versatility for a wide range of materials, including aluminum alloy, aluminum-wood composites, copper profiles, and U-PVC. Featuring a cutting-edge CNC system with an intuitive human-machine interface, the equipment supports 4-axis linkage machining (90°~0°~-90°) and enables multi-functional operations such as milling, drilling, chamfering, and slotting in a single clamping. Built with a high-strength welded structure and stress-relief heat treatment, it ensures exceptional rigidity and stability for long-term use.

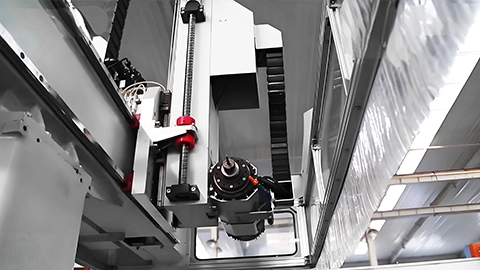

The machine incorporates imported high-precision linear guides, ball screws, gear racks, and a digital servo system for smooth, accurate, and reliable motion. A high-speed automatic tool-changing spindle, sourced from Italy, provides superior cutting performance with low noise and enhanced stability. Its 6-position tool magazine and eight pneumatic clamps optimize processing efficiency, while the dual worktables allow simultaneous or alternating processing of two profiles, significantly boosting productivity.

In addition, the equipment is equipped with an automatic tool-length detector, a spray cooling system, and a professional industrial control system with imported components for precise, consistent, and efficient operation. Supporting both online and offline programming, it offers maximum flexibility for production demands. With its rigorous quality management, robust design, and state-of-the-art features, this equipment represents a superior solution for modern door and window manufacturing needs.

Automatic Four-axis CNC Aluminum Milling Machine (Cantilever) Parameters

Cutting

| X-axis Range | 7000mm |

| Y-axis Range | 1400mm |

| Z-axis Range | 600mm |

| Spindle Range | -90°~0°~+90° |

| Max Cutter Length | 165mm |

| Saw Blade Diameter | Ф80~Ф150mm |

| Working Area (W×H×L) | 650×200×7000mm |

| Machine Size (L×W×H) | 11300×2350×2550mm |

Power

| Spindle Power | 7.5kW |

| Air Pressure | 0.5~0.8MPa |

| Input Voltage | 380V/50Hz |

| Total Power | 13kW |

Machine

| X-axis Speed | 0~60m/min |

| Y-axis Speed | 0~30m/min |

| Z-axis Speed | 0~20m/min |

| Spindle Speed | 0~18000r/min |

| Fixture Quantity | 8 Set |

| Lubrication Method | Auto Lubricating |

| Cooling Method | Spray Cooling |

| Machine Weight | 4500kg |

Automatic Four-axis CNC Aluminum Milling Machine (Cantilever) Details

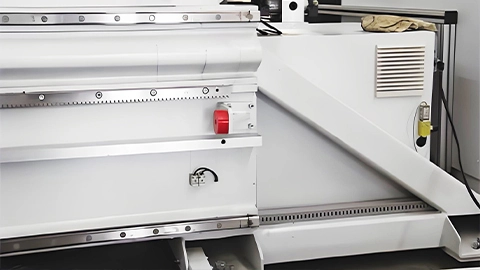

Loading System

Guide Rail System

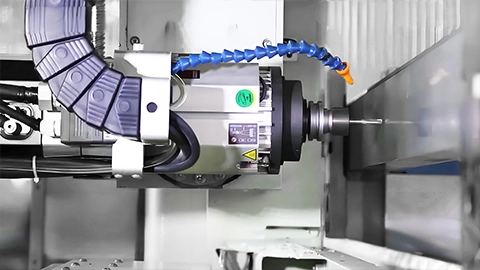

Cantilever Four-Axis Machining

Cantilever Processing System

High-Precision Drilling and Milling