Double-axis CNC Aluminium Milling Machine

The Double-axis CNC Aluminium Milling Machine is designed for processing standard and reinforced mullion profiles in aluminum alloy structures.

Double-axis CNC Aluminium Milling Machine Features

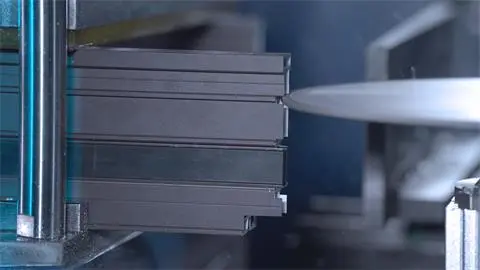

The Double-axis CNC Aluminium Milling Machine is designed for processing standard and reinforced aluminum mullion profiles with high precision and efficiency. Equipped with a vertical cutting saw blade, the machine ensures that the end face of reinforced mullion profiles is completed in one milling operation, enhancing productivity. The system allows simultaneous milling of multiple profiles in a single feed, significantly improving operational efficiency.

The cutting tool can be adjusted vertically and horizontally, enabling the machining of stepped surfaces, rectangular slots, and other complex structures. Featuring a large-diameter tool, the machine achieves high cutting speeds and superior surface quality. The mechanical rack transmission combined with a frequency conversion motor for speed regulation ensures smooth and stable operation. Independent speed adjustments for forward and backward motion further optimize machining efficiency.

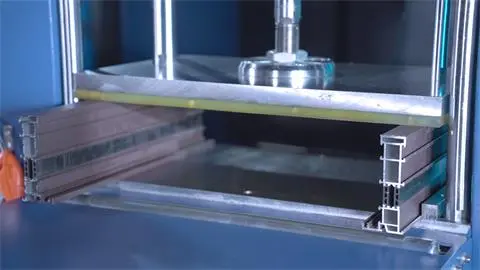

The pressure plate is equipped with four guiding shafts and bearings, ensuring even pressure distribution and preventing profile deformation for more reliable clamping. Additionally, the phase sequence protection device effectively safeguards the equipment against phase loss or incorrect phase connections, enhancing operational safety and longevity.

Double-axis CNC Aluminium Milling Machine Parameters

Cutting

| Work Table Width | 400mm |

| Max Tenoning | 180mm |

| End Mill Size | Ф250×Ф32mm |

Power

| Air Pressure | 0.6~0.8MPa |

| Input Voltage | 380V/50Hz |

| Input Power | 2×3.0kW |

Machine

| Rotational Speed | 2800r/min |

| Machine Size | 1400×1160×1650mm |

| Machine Weight | 730kg |

Double-axis CNC Aluminium Milling Machine Details

Easy Operating Console

Automatic material clamping system