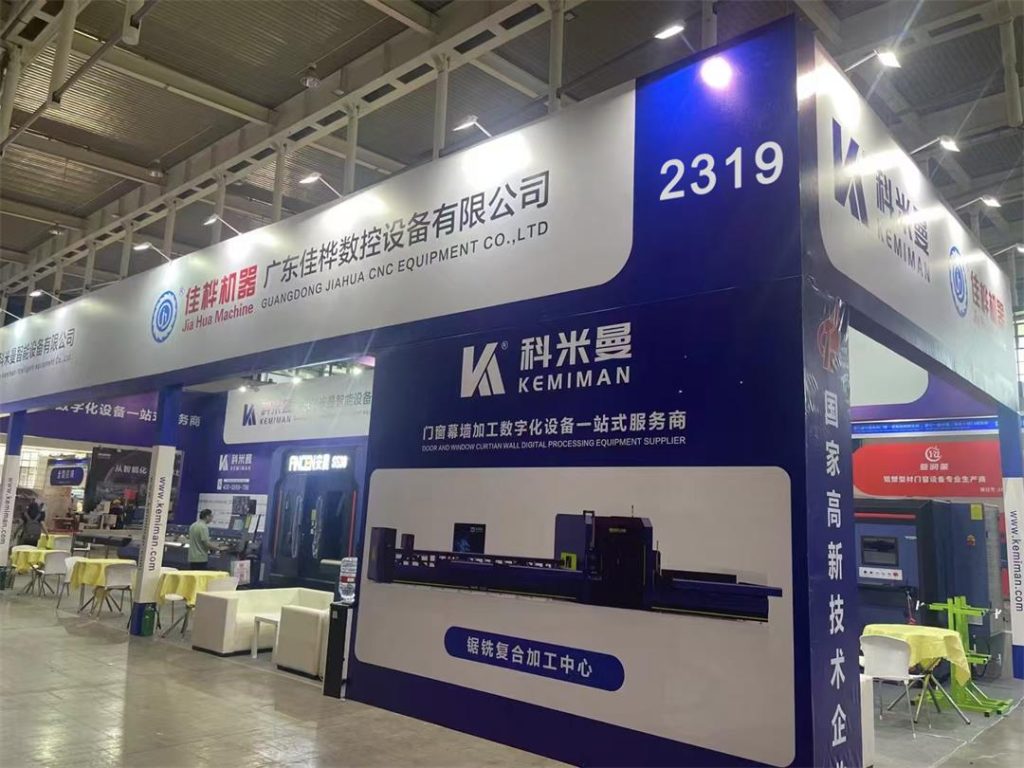

At the 2023 FBC Fenestration Building China Expo (Shanghai•National Exhibition and Convention Center, Booth: 2.2 Hall 2319, Date: August 3rd-6th), JH Machine, the expert in door and window equipment manufacturing, unveiled its groundbreaking creation: the KMM-S530 Intelligent Aluminum Profile Machining Center! This innovative equipment, integrating the advantages of Intelligent Aluminum Profile Cutting Machine and Intelligent Aluminum Profile Milling Machine, became an instant sensation upon its debut. With its exceptional performance and high-efficiency processing capabilities, it captivated numerous customers, resulting in continuous orders placed on-site and solidifying its status as an undisputed star product.

KMM-S530: Redefining Intelligent Aluminum Window Making Machine:

The KMM-S530 Intelligent Processing Center breaks through traditional processing models by innovatively integrating cutting, drilling, milling, and laser marking into one comprehensive unit, truly achieving “One Machine, Multiple Processes.”

Processing, Efficiency Multiplied: Integrating cutting, drilling, milling, and laser marking into one machine eliminates the traditional multi-station, multi-process machining model, significantly shortening processing workflows, saving labor costs, and boosting production efficiency.

Intelligent Servo, Parameter Self-Adaptation: Equipped with a full servo control feeding system, it can intelligently recognize aluminum profile parameters (height, wall thickness) and intelligently adjust processing parameters (feed speed, feed position) based on profile characteristics, ensuring optimal processing results. It also features a built-in error prevention system to avoid human errors.

ERP Interconnection, Intelligent Manufacturing Upgrade: Supports connection with ERP software, seamlessly integrating with enterprise production management systems to achieve a fully automated process from order to production. This builds an intelligent production line and enhances the level of digital management for enterprises.

Intelligent Management, Controllable Delivery: Equipped with a tool life management system, automatic maintenance and upkeep prompts, as well as production capacity and equipment status statistics functions, it enables real-time monitoring of equipment operation status. This provides enterprises with precise production data support, ensuring controllable delivery times and effectively reducing inventory backlog.

Remote Service, Worry-Free After-Sales: The powerful remote service function allows JH Machine’s professional engineers to respond quickly and complete after-sales service support such as equipment maintenance and upkeep as long as the equipment is connected to the internet. This minimizes equipment downtime and reduces the company’s reliance on skilled technicians.

Widely Applied to Various Aluminum Products:

The KMM-S530 Intelligent Processing Center can be widely used for the high-efficiency and precision processing of:

- Aluminum Alloy Doors and Windows

- Curtain Wall Profiles

- Industrial Aluminum Profiles

- …and many other aluminum profiles, meeting the processing needs of different industries and fields.

Exhibition Grandeur:

At the FBC Expo, the KMM-S530 Intelligent Processing Center, with its core advantages of “high efficiency, intelligence, and composite processing,” attracted numerous professional visitors to stop and inquire, receiving high praise. Many customers expressed appreciation for the intelligent level and high-efficiency processing capability of the KMM-S530 and signed purchase contracts on the spot, fully demonstrating the market’s high recognition of JH Machine’s intelligent equipment.

Reasons to Choose JH Machine KMM-S530:

- Innovative Processing Technology, Leading Industry Trends: The KMM-S530 represents the latest technological direction in aluminum profile processing equipment, helping enterprises seize market opportunities.

- Intelligent Production Management, Enhancing Enterprise Competitiveness: From equipment to management, a comprehensive intelligent upgrade helps companies reduce costs, improve efficiency, optimize management, and enhance core competitiveness.

- Comprehensive Intelligent Services, Ensuring Worry-Free Production: From intelligent equipment to remote services, JH Machine provides you with comprehensive intelligent solutions, ensuring worry-free production.

- 30 Years of Brand Accumulation, Quality You Can Trust: JH Machine’s 30 years of professional manufacturing experience, striving for excellence, ensures that every piece of equipment undergoes strict quality control, guaranteeing stability and reliability, worthy of your trust.

- Contact JH Machine Now to Schedule a Visit to the KMM-S530 Intelligent Cutting, Drilling, Milling, Laser Processing Center and Begin Your Efficient Journey to Intelligent Manufacturing!

Want to learn about starting your business?

Contact us now!