In the fiercely competitive door and window processing industry, efficiency and cost control are paramount. JH Machine, with over 30 years of industry experience, proudly introduces the KMM-S530 Intelligent Aluminum Profile Machining Center, bringing a revolutionary solution to aluminum window and door manufacturers. This equipment is not only high-efficiency aluminum window making machine but also your ideal choice for achieving intelligent production and enhancing market competitiveness.

One-Stop Intelligent Processing, Multi-Process Integration, Efficiency Increased by 3 Times

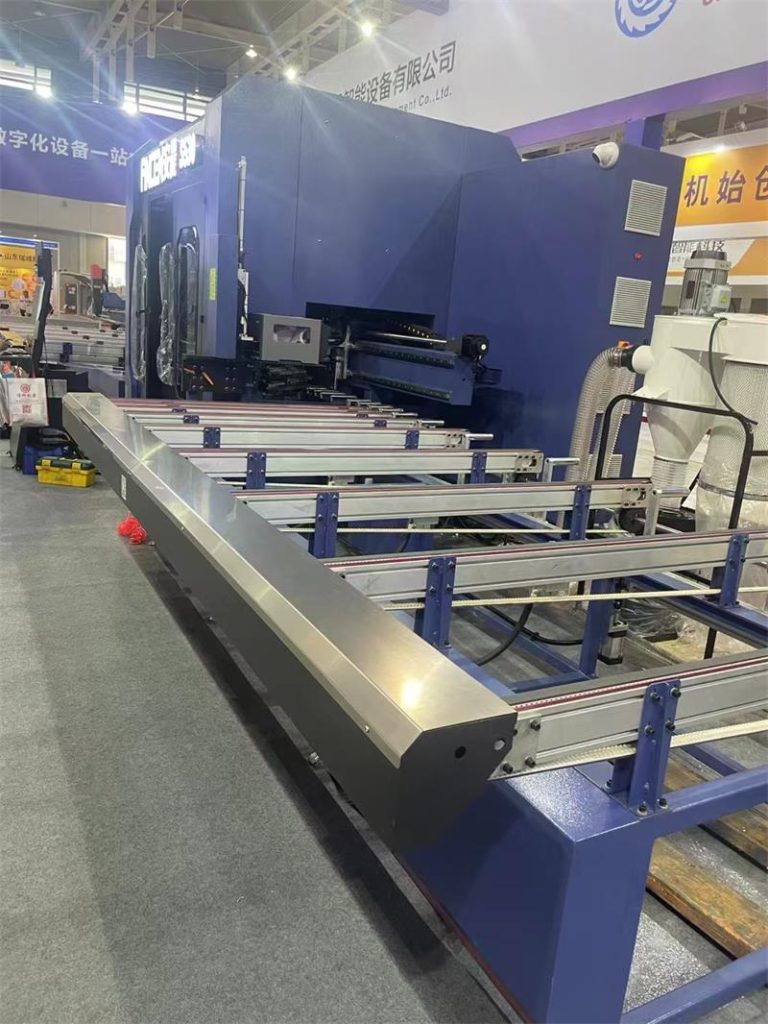

The KMM-S530 Intelligent Aluminum Profile Machining Center integrates multiple functions such as cutting, drilling, milling, and laser marking, truly realizing the dream of completing multiple processes on one machine. Traditional aluminum window making machine requires multiple machines and workers to operate collaboratively, while the KMM-S530 only needs one machine to complete:

Precision hole processing such as dowel pin holes and glue injection holes

Special structure processing such as mullion scribing, invisible drainage holes, and floor drain holes

Hardware installation position processing such as lock box holes, corner protectors, and drive rod notches

One machine replaces multiple, greatly saving equipment investment and floor space. Production efficiency is increased by 3 times compared to traditional processing methods, significantly reducing labor costs and improving production efficiency.

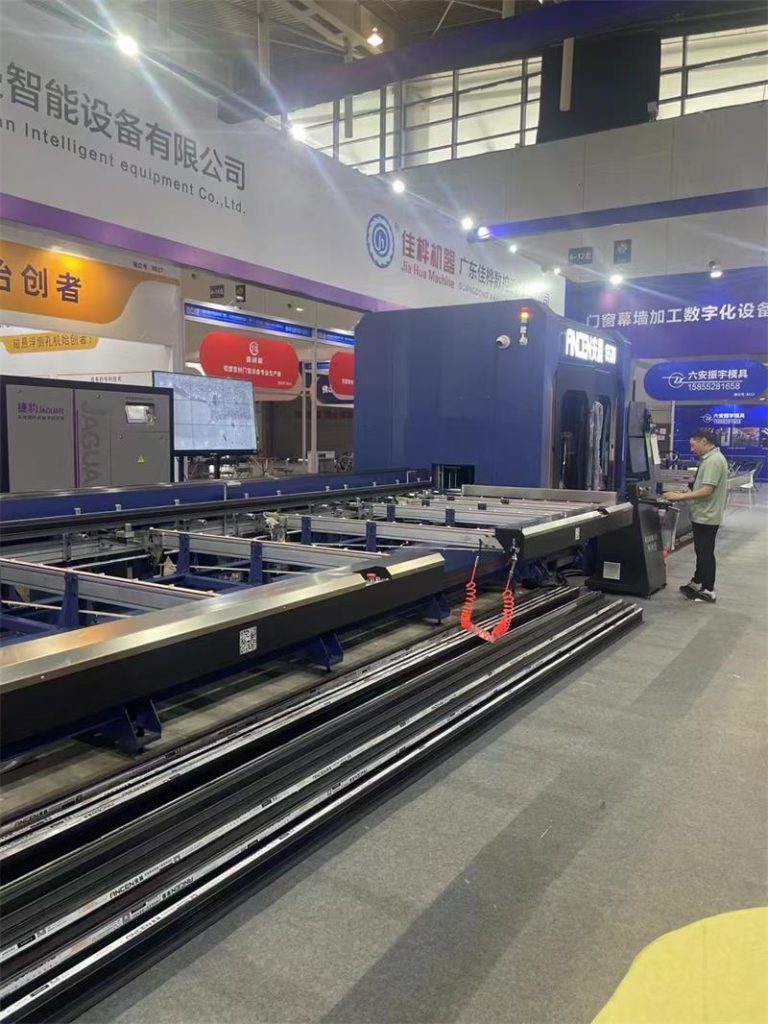

Intelligent Parameter Recognition, Simple Operation, Easy for Ordinary Workers to Master

The KMM-S530 Intelligent Aluminum Profile Machining Center is equipped with a full servo control feeding system that intelligently recognizes aluminum profile parameters (height, wall thickness) and intelligently adjusts processing parameters (feed speed, feed position) without manual intervention. It also has a built-in error prevention system to avoid human operational errors.

The equipment’s operation interface is user-friendly, requiring no skilled workers, no consideration of profile section height, and no custom molds. Ordinary workers can easily complete production tasks, greatly reducing the reliance on skilled workers and solving the challenges of labor shortages and high labor costs for enterprises.

Intelligent Production Management, Seamless Connection with ERP Systems

The KMM-S530 Intelligent Aluminum Profile Machining Center can be seamlessly connected with ERP software to achieve scan code processing. Production data is uploaded in real-time, helping enterprises build a fully automated production management system and improve the refinement and intelligence level of production management.

Remote Intelligent Service, Ensuring Production Continuity

JH Machine also provides remote services, including equipment maintenance, upkeep, and training, saving service time and reducing downtime, ensuring the continuous operation of customers’ production lines and giving you peace of mind.

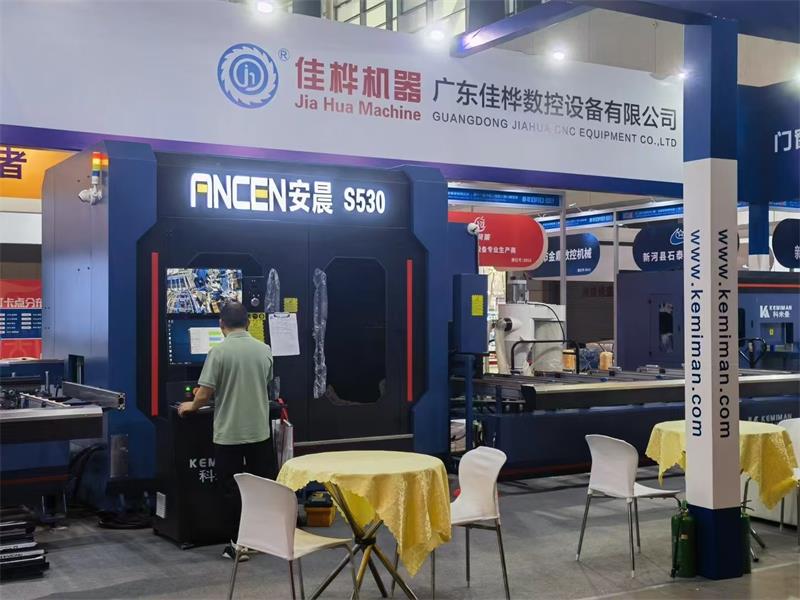

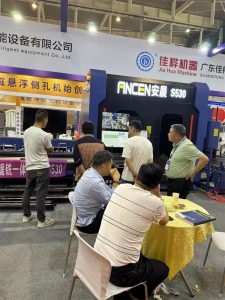

Exhibition Review: Nanjing Door & Window Customized Exhibition, Continuous Customer Praise

At the 11th Nanjing Door & Window Customized Exhibition, the KMM-S530 Intelligent Aluminum Profile Machining Center attracted the attention of many professional visitors as soon as it was unveiled. With its intelligent and efficient aluminum window production solutions, solid materials, and excellent value for money, it was deeply loved by customers, and the booth was bustling with popularity (Booth No.: Nanjing International Expo Center 8B13, May 9-11, 2024).

Choose JH Machine, Choose Intelligent and Efficient Aluminum Window Making Machine, Seize Market Opportunities!

To learn more about the KMM-S530 Intelligent Aluminum Profile Machining Center and JH Machine’s aluminum window making machines, please visit our website and subscribe below to contact us.

Want to learn about starting your business?

Contact us now!