Thermal Break Aluminum Machine for Aluminium Profile Knurling and Strip Insertion

Thermal Break Aluminum Machine Features

This machine plays a crucial role in the production of thermal break aluminum profiles, ensuring a tight and accurate bond between the thermal break strip and the aluminum profile, thereby enhancing the thermal insulation properties and structural strength of the composite profile.

Key Features:

1. Efficient Knurling and Insertion: The machine presses the cutting head into the profile groove and utilizes the rotation of the cutting head to draw the profile, rolling knurling patterns inside the profile while simultaneously inserting the thermal break strip or plastic profile.

2. Enhanced Shear Strength: The knurling and texturing process effectively increases the lateral shear strength of the profile, improving the overall performance of the composite profile.

3. Suitable for Large Profiles: Featuring an open-type knurling structure, the machine is particularly suitable for processing large aluminum profiles, accommodating various production requirements.

Thermal Break Aluminum Machine Parameters

Processing

| Transmission Speed | 10~60m/min |

| Knurling Diameter | 100mm |

| Knurling Spacing | 8~240mm |

| Max Horizontal Range of Knurling | 240mm |

| Max Vertical Range of Knurling | 280mm |

| Maximum Processing Cross Section | 230mm×280mm |

Power

| Input Power | 2×0.55kW |

| Input Voltage | 380V/220V 50Hz |

Machine

| Machine Size | 900mm×950mm×1420mm |

| Machine Weight | 600kg |

| Rack Size | 5000mm×420mm×1000mm |

Thermal Break Aluminum Machine Details

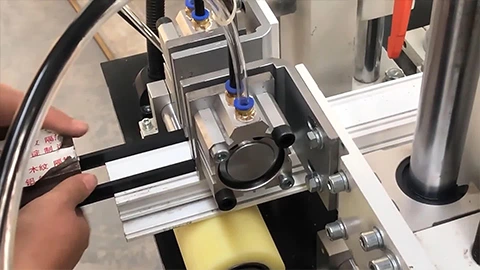

High-quality Tooth Opening System

High-speed Traction Device

Reliable Main Motor

Stable Nylon Rollers