Thermal Break Assembly Machine Center for Aluminium Profile Rolling

Thermal Break Assembly Machine Center Features

This machine is indispensable for the production of thermal break aluminum profiles, ensuring the thermal strips are securely and accurately bonded to the aluminum profiles.

Key Features:

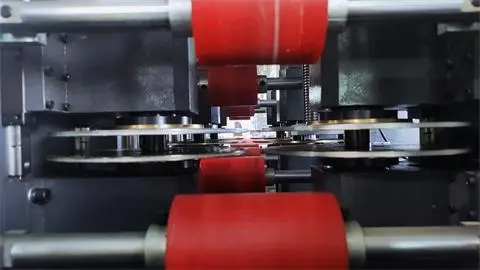

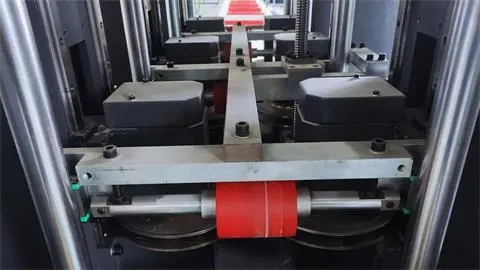

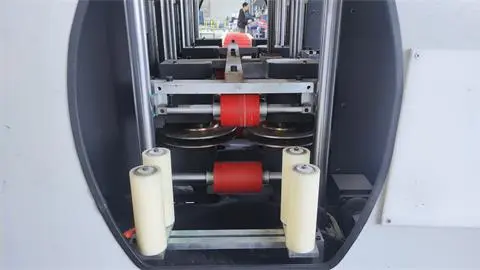

1. Hydraulic Rolling Mechanism: Equipped with three sets of six rolling wheel assemblies, the machine compresses the grooves of aluminum profiles that have been fitted with thermal strips, ensuring a strong connection between the aluminum profiles.

2. Precise Pressure Control: Utilizing three pressure sensors, the machine allows for precise pressure adjustments via an electronic display, ensuring consistent rolling quality.

3. Versatile Processing: Capable of handling various sizes and shapes of materials, the processing range can be customized to meet specific requirements.

4. Advanced CNC Technology: Our CNC equipment is more advanced and intelligent, capable of connecting with other devices to enhance automation and production efficiency.

Thermal Break Assembly Machine Center Parameters

Processing

| Processing Speed | 0~70m/min |

| Profile Size | 280×280mm |

| Roller Diameter | Ф230mm |

| Auxiliary Frame (W×L) | 500×5500mm |

| Feeding Speed | 6~60m/min |

Power

| Input Power | 3.5kW |

| Input Voltage | 380V/50Hz |

Machine

| Machine Size | 1000×1100×1550mm |

Thermal Break Assembly Machine Center Details

Durable Rollers

Six Rollers

Nylon Rollers

Three Pressure Control Systems